Custom Material Converting

Material converting is the process of transforming raw materials into components, disposable devices, or complex, multi-layer products through a variety of fabrication processes. At ADDEV Materials Healthcare, we specialize in numerous custom material converting processes, including:

Material converting is the process of transforming raw materials into components, disposable devices, or complex, multi-layer products through a variety of fabrication processes. At ADDEV Materials Healthcare, we specialize in numerous custom material converting processes, including:

- Kiss cutting

- Slitting

- Sheeting

- Perforating

- Scoring

- Rewinding

- Multi-layer laminating

- Cold seal packaging

- Island placement

- Printing

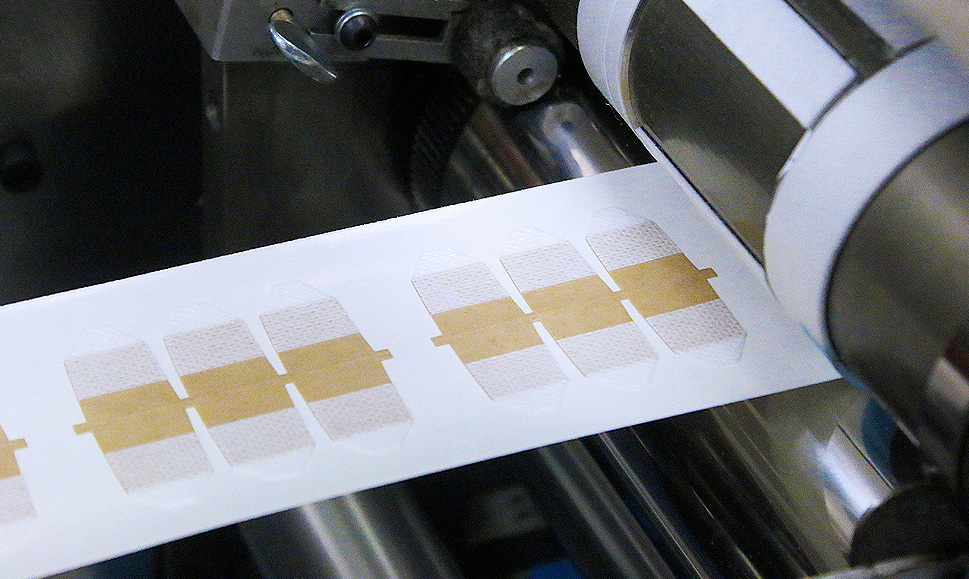

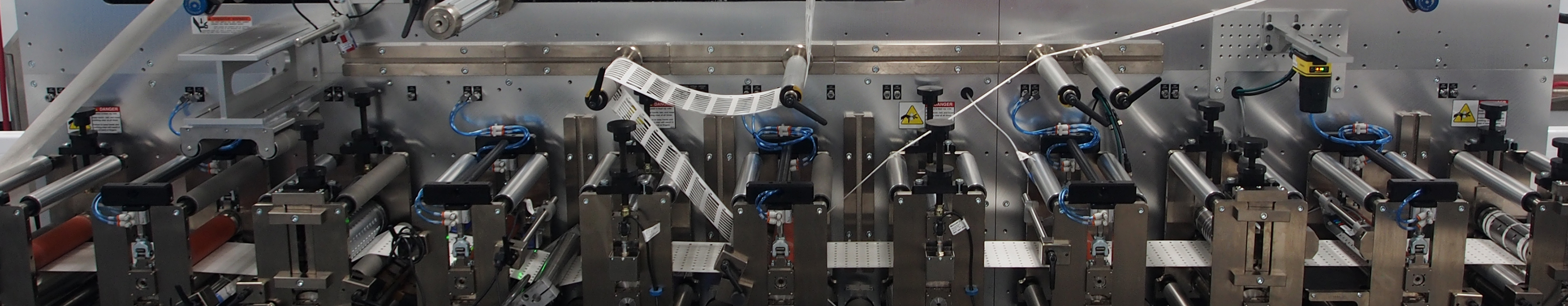

- Precision Rotary Die Cutting

As a Solventum Premier Converter, one of only a handful in the US, we have the experience and capability to convert flexible materials into finished products in roll, individual parts, or sheeted format. We use industry-leading, narrow web, rotary die cutting presses with advanced servo technology, closed-loop registration, and in-line vision inspection, along with the best craftsmen in the business, to manufacture precision products for many markets and applications.

Whether you’re making a medical device, automotive product, communications components, or anything in between, you will likely want to alter and form materials to fit your unique design. That’s where a custom converter like ADDEV Materials Healthcare can be a valuable partner.

ADDEV Materials Healthcare Converting Processes

While the possibilities with converting are virtually endless, there are a few common processes used in product manufacturing:

- Laminating: Combining two or more materials into one. Can include adhesives, tapes, foams, and many other substrates.

- Slitting: Starting with a large roll, cut the material into a more specific size for your needs.

- Die-cutting: Forming specific shapes from raw material. Based on specifications, die-cutting can be accomplished through a range of processes, including clam-shell, flatbed, and rotary.

Partnering with an experienced custom converter like ADDEV Materials Healthcare will not only allow you to take advantage of these capabilities but also combine them with different materials to improve the design and performance of your product. Let ADDEV Materials Healthcare be your trusted partner in material converting.

Highlighted Services

Material Selection

Single and double-coated tapes and transfer adhesives can be used to achieve desired results. ADDEV Materials Healthcare can assist with material and adhesive selection.

- Adhesives

- Films

- Fabrics

- Foams

- Foils

- Hydrocolloids

- Hydrogels

- Inks

- Non-wovens

- Papers

- Tapes

Markets and Applications

It takes the right mix of material knowledge, precision equipment, and technical expertise to manufacture multi-layer, die cut products.

- Diagnostics

- Ostomy

- Patient Monitoring

- Personal Care

- Pharmaceuticals

- Surgical

- Wearables

- Wound Care

Quality System

ADDEV Materials Healthcare is committed to continuous improvement. Our Quality Management System (QMS) provides a solid framework to ensure risks are understood and processes are in control.

In partnership, our team will help you determine the best raw materials, product design, and manufacturing process to meet your product's performance requirements.

- ISO 13485:2016 Registered

- FDA Registered Medical Device Manufacturer

- cGMP Compliant to 21 CFR 210, 211, and 820

What Can We Do for Your Business?

Call us 262.255.6150 or send a message to sales.amh@addevmaterials.com TODAY to connect with a specialist about your custom product.

Let's Get Started