Clean Room Manufacturing

If your product requires that manufacturing and/or assembly is done in a clean, climate-controlled, and FDA registered production facility, ADDEV Materials Healthcare can help. We operate ISO Class 7 and ISO Class 8 certified cleanrooms for manufacturing converted products.

If your product requires that manufacturing and/or assembly is done in a clean, climate-controlled, and FDA registered production facility, ADDEV Materials Healthcare can help. We operate ISO Class 7 and ISO Class 8 certified cleanrooms for manufacturing converted products.

What Is a Cleanroom?

A cleanroom or clean room is designed to maintain extremely low levels of particulates, such as dust, chemical vapors, aerosol particles or airborne organisms. Moisture and air particles can be detrimental to medical and electronic products. If adhesives and flexible materials are exposed to airborne particles and moisture, they can be contaminated. This exposure shortens the product’s shelf life and can negatively impact the performance of the product. Cleanrooms typically have a cleanliness level quantified by the number of particles per cubic meter at a predetermined molecule measure.

The air outside in a typical urban environment contains 35,000,000 particles per cubic meter with a size of 0.5 micron and larger in diameter. In comparison, an ISO Class 1 cleanroom contains just 12 particles per cubic meter with a size of 0.3 micron and smaller. The air in a clean room is filtered and cooled by several outdoor air filters (HEPA and/or ULPA) using progressively finer filters to exclude dust and particles.

Who Benefits from Utilizing a Cleanroom?

Cleanrooms are used in practically every industry where small particles can adversely affect the manufacturing process. A few of the high-demand markets such as medical devices, pharmaceuticals, electronics, and others benefit from the tight control of air quality provided by our cleanrooms. ADDEV Materials Healthcare manufactures products under the requirements of our Quality Management System (QMS). We are ISO 13485:2016 certified, FDA registered, and cGMP compliant.

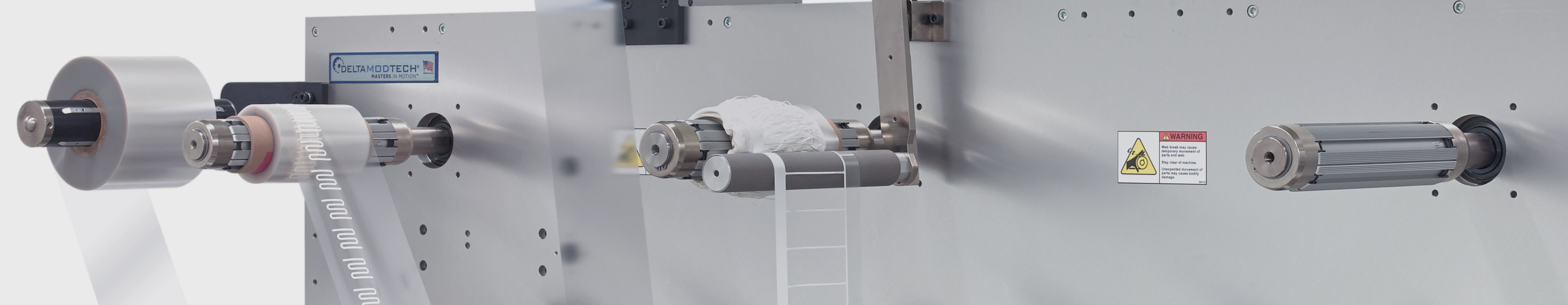

AMH’s converting capabilities include precision rotary die cutting, kiss cutting, slitting, perforating, scoring, printing, multi-layer laminating, cold seal packaging, and island placement. As a Solventum Premier Converter, one of only a handful in the US, we have the experience and capability to convert materials into die cut components and finished disposable devices - roll and sheet fed. If you would like more information on cleanrooms to confirm your project requirements, or if you'd like a quote, give us a call to speak to one of our experts.

What Can We Do for Your Business?

Call us 262.255.6150 or send a message to sales.amh@addevmaterials.com TODAY to connect with a specialist about your custom product.

Let's Get Started